Manufactory

Welcome to our watchmaking workshop in Nové Město nad Metují, where we create timepieces with unique character. Each watch is the result of meticulous craftsmanship by our skilled horologists, who combine traditional techniques with modern technology. Our watches are not just tools to measure time; they are a reflection of your personality and style.

Inspired by our Czech heritage, we design every detail to bring you joy and reliability for years to come. We prioritize quality, precision, and attention to detail in every piece we produce.

Discover watches crafted with passion and care, just for you. Step into a world where time is measured by perfection.

Watchmaking process

Mechanical movement

When designing a new watch we have to define the functions and complications of the movement in line with the model’s character. Working with our Swiss partners we design a movement which made specifically for each model.

For instance, the caliber made for the Minor model has uniquely skeletonised bridges, a custom-designed rotor and a skeletonised date wheel which is made in collaboration with Czech producers and decorated by our watchmakers. The movements can be personalised further according to your wishes.

Case, case back and bezel

The parts that give our watches their appearance are designed in-house from scratch. It is a multistep process starting from an idea to a series of sketches, 3D models and 2D production drawings. The parts are machined out of European origin materials in Switzerland and finished by hand by us in our workshop.

We employ a range of surface finishes to achieve the ideal look for each model. These include polishing, burnishing, brushing and various methods of blasting that produce different shades and characters of sheen. The technologies can be combined for stunning results. In some cases, we also use electroplating or electroforming to alter the colour ort he mechanical qualities of the surface.

And on top of all that we offer a wide range of decorative techniques to personalise these principal components of your watch giving you the opportunity to wear a truly unique timepiece on your wrist.

Dial

Technologically, the dial is a very demanding part to make. The starting point is making a perfect master which is then multiplied through a process called electrodeposition. You can imagine the process like “growing” dials in the image of the master.

And that’s just the beginning. A number of decorative and finishing techniques follow – metal plating, attaching indices, printing designs to name just a few. There are easier ways of making dials but none of them offers as many finish options as this one.

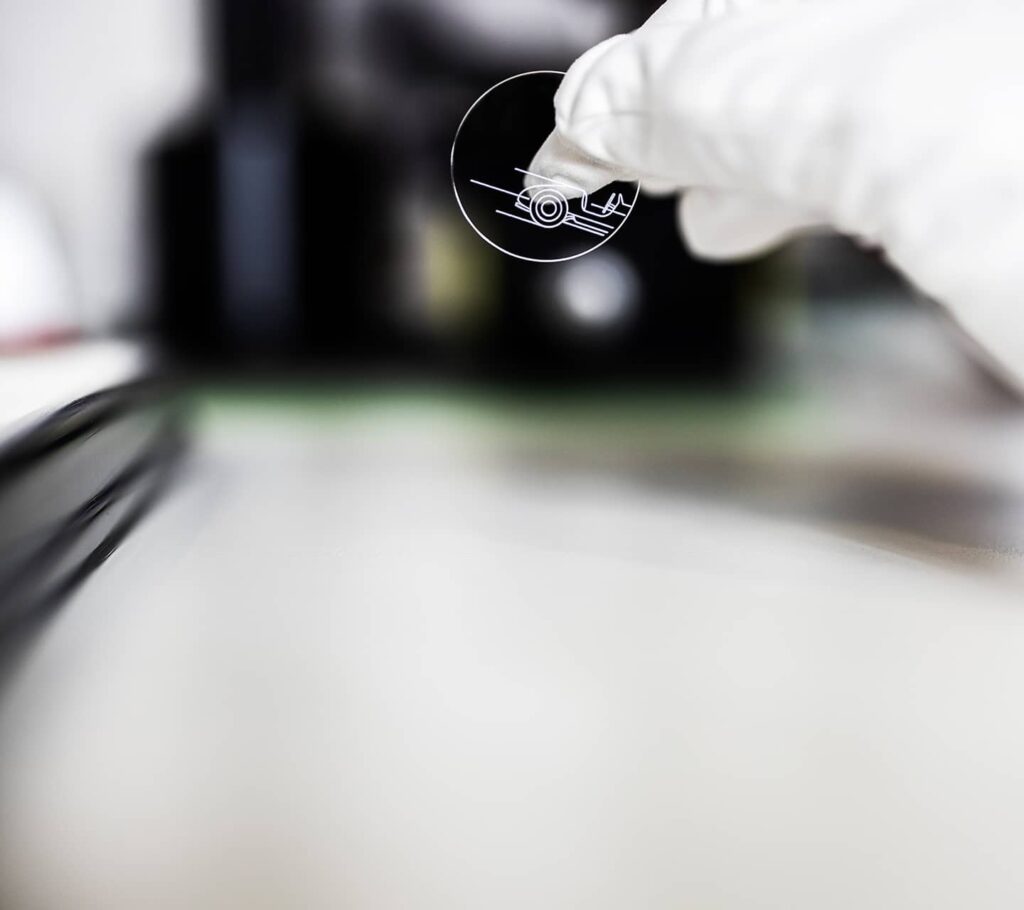

Crystal

The spherical crystals of our watches are made of sapphire. Their shape plays an important part in the overall appearance of the watch and our designers pay them a lot of attention. They are made in Switzerland and their back is coated with a thin layer of antireflective material. The reason why we use sapphire crystals is simple – they are very hard and therefore virtually scratch-proof. The most popular method of personalising the crystal of your watch is printing.

Hour and minute hands

The hands of ROBOT watches are machined and that enables us to combine various finishes such as polished edges and brushed or blasted surfaces. The final electroplating of the hands preserves the structure of the surface and adds an extra dimension to their appearance. Finishing the hands often involves another step – the application of luminescent material. This decoration, which has both an aesthetic as well as functional purpose, is done under a microscope by a special pen. The most important part of the process, however, is a precise and steady hand of an experienced watchmaker.

Sweep seconds hand

The central seconds hand is not the most important time indicator on any watch but we see it as one of the most attractive details. We pay it the utmost attention – from the original design to the technical drawings and the finishing of it by hand.

It is a very demanding job for a watchmaker to achieve a mirror finish on such a minuscule object. To give the seconds hand the beautiful metalic blue shade, it is heat treated in a process called annealing. The important trick of the trade is an even distribution of heat. Differences in the order of single degrees may spoil the final result.

ROBOT customers who like the seconds hand as much as we do often have it personalised by adding their intitials or a miniature of a dear object. When this happens, we enjoy the making of it even more. And if you prefer your seconds hand in red we’ll be happy to oblige.

Cap

The cap that holds the seconds hand on the shaft is machined first and then finished by hand. We can finish the surface by mirror polishing, straight or pattern brushing and a range of blasting techniques. The techniques can be combined to achieve a very attractive result. The last step in the process is electroplating which adds the right shade while preserving the surface structure.

The cap can also be painted in gloss or matt paints which is the preferred option for those who want their watch to show their favourite colour. It might seem excessive to devote so much attention to such a tiny part but the result can be stunning and well worth the effort.

Crown

The crown is the proverbial cherry on the cake and we pay a lot of attention to it. From the original design to its finishing we give it a lot of time and thought. Like the other parts, it is machined by our production partner and then finished in our workshop. The crown can be decorated using all the previously described finishing methods. Custom decoration of the crown is one of the most popular personalisation options.

Strap

A ROBOT watch and hand-sewn leather strap made by SimaPrague go literally hand in hand. Thanks to our collaboration with this leading producer our designers can be sure that their ideas will materialise without compromises. The greatest advantage of hand made straps is the customisation of colours, shapes, lengths and stitching details.

Blue

Blue  Silver

Silver  Blue

Blue  Black

Black  Silver

Silver  Blue

Blue  BRONZE AURA PVD

BRONZE AURA PVD  INDY SUNBURN

INDY SUNBURN  LE MANS BLUE

LE MANS BLUE  MONACO BLACK

MONACO BLACK  SPA GREY

SPA GREY  BLACK NICKEL

BLACK NICKEL  BRONZE AURA PVD

BRONZE AURA PVD  COBALT BLUE

COBALT BLUE  COPPER BROWN

COPPER BROWN  SILVER METALIC

SILVER METALIC  STREAMLINE BEIGE

STREAMLINE BEIGE  TITANIUM GREEN

TITANIUM GREEN  AURA

AURA  NERA

NERA  SILVER

SILVER  BLACK

BLACK  BLUE

BLUE  BROWN

BROWN  GREY

GREY  GREY SUN

GREY SUN  IVORY

IVORY  PINK

PINK  SILVER

SILVER  SILVER SUN

SILVER SUN  WHITE

WHITE  BLACK

BLACK  SILVER

SILVER  BRONZE AURA PVD

BRONZE AURA PVD  CAMEL ARDOISE

CAMEL ARDOISE  CHAMELEON GREEN

CHAMELEON GREEN  ELEPHANT BLUE

ELEPHANT BLUE  RHINO BLACK

RHINO BLACK  TAPIR WHITE

TAPIR WHITE  WALRUS SILVER

WALRUS SILVER